3D printing technology has revolutionized the way we create objects and bring our designs to life. With the advancement of 3D printing, two popular methods have emerged: SLA (Stereolithography) and FDM (Fused Deposition Modeling). Both methods have their unique characteristics, benefits, and limitations, especially when it comes to achieving smooth surface finishes. In this article, we will explore the differences between SLA and FDM 3D printing in terms of surface smoothness and the impact of using different materials and techniques to achieve a superior finish.

SLA 3D Printing

SLA 3D printing, or stereolithography, is a process that utilizes a vat of liquid resin cured by UV light to create solid objects layer by layer. One of the key advantages of SLA printing is its ability to produce exceptionally smooth surfaces, making it ideal for creating intricate and detailed parts with fine features. The precision and accuracy of SLA printing result in minimal visible layer lines, contributing to a high-quality surface finish.

SLA 3D printers are capable of producing objects with intricate details and smooth curves, making them well-suited for applications such as jewelry, dental products, and prototyping. The smooth surface finish achieved by SLA printing can significantly reduce the need for post-processing, saving time and effort in the production process.

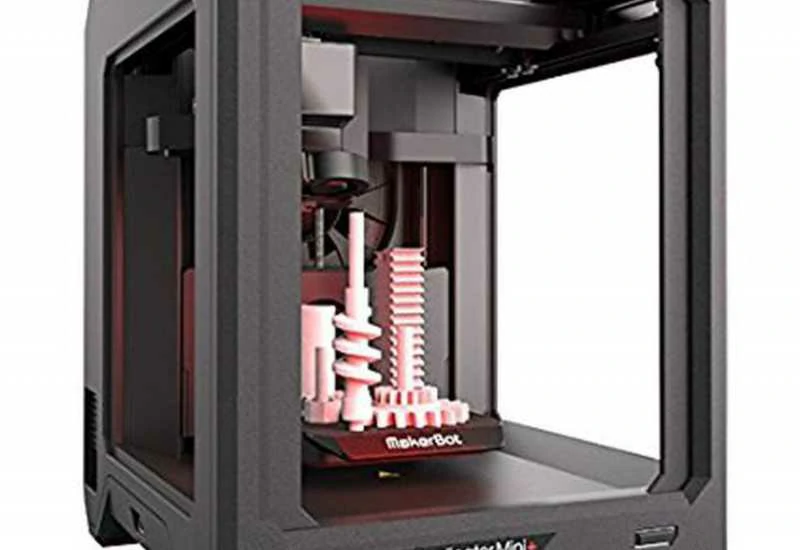

FDM 3D Printing

FDM, or fused deposition modeling, is another widely used 3D printing method that operates by extruding thermoplastic filaments layer by layer to build objects. While FDM printers are versatile and cost-effective, achieving a smooth surface finish can be more challenging compared to SLA printing. The layer-by-layer deposition of molten plastic results in visible striations and texture on the printed object’s surface, requiring additional finishing processes to achieve a smoother appearance.

Surface Smoothness Comparison

When comparing the surface smoothness of objects produced using SLA and FDM 3D printing, it is evident that SLA-printed parts typically exhibit a superior level of smoothness and detail. The layer lines on SLA-printed objects are significantly less noticeable, resulting in a near injection-molded quality finish.

In contrast, FDM-printed parts often require post-processing techniques such as sanding, priming, and painting to achieve a smoother surface finish. However, advancements in FDM technology, including improved print settings, finer nozzles, and specialized post-processing methods, have made it possible to enhance the surface smoothness of FDM-printed objects.

Materials and Techniques for Smooth 3D Printing

In both SLA and FDM 3D printing, the choice of materials and specific printing techniques can greatly influence the final surface smoothness of printed objects. In SLA printing, opting for low-viscosity resins and utilizing advanced support removal processes can contribute to smoother finishes, minimizing the need for extensive post-processing.

For FDM printing, selecting filaments with fine particles and incorporating features such as cooling fans and enclosed build chambers can help mitigate issues related to layer adhesion and improve surface quality. Additionally, employing sanding, vapor smoothing, and specialized coatings can further enhance the smoothness of FDM-printed parts, allowing for a more refined appearance.

Applications and Considerations

The choice between SLA and FDM 3D printing for achieving smooth surface finishes depends on the specific requirements of the intended application. SLA printing excels in producing intricate, detailed parts with a high degree of smoothness, making it suitable for applications where aesthetics and precision are paramount. Industries such as medical, jewelry, and product design often benefit from the superior surface finish offered by SLA technology.

On the other hand, FDM printing remains a preferred choice for rapid prototyping, functional parts, and large-scale manufacturing due to its cost-effectiveness and versatility. While achieving a smooth surface finish may require additional effort, advancements in FDM technology continue to bridge the gap, offering competitive results in various applications.

Conclusion

In conclusion, the pursuit of smooth surface finishes in 3D printing is a driving force behind technological advancements and material innovations in both SLA and FDM methods. While SLA 3D printing inherently provides superior surface smoothness, developments in FDM technology and the use of advanced materials and techniques have narrowed the gap, offering viable solutions for achieving quality finishes.

As 3D printing continues to evolve, the ability to produce smooth, high-quality surfaces will play a crucial role in expanding its applications across industries and driving further innovation in additive manufacturing. By understanding the nuances of each 3D printing method and leveraging the right materials and techniques, manufacturers and designers can unlock the full potential of 3D printing and deliver exceptional results with smooth surface finishes.

.webp)